Product Description

Patrameter table:

| Grade |

Standard |

Outside Diameter |

8mm-711mm |

Alloy 600

Alloy 601

Alloy 625

Alloy 825

Alloy 800/800H/800HT

Alloy C276

Alloy C22

Alloy 400

Alloy K500

Alloy 200

Alloy 201

... |

ASTM-B444

ASTM-B167/163

ASTM-B622

ASTM-B423

...... |

Wall Thickness |

1mm-50mm |

| Length |

≤20m |

| Inspection |

Appearance/ Dimensional test, PMI;

NDT: UT/ ET/ HT;

Physical & chemical test |

| Certificates |

ISO/PED/AD2000/TS |

| Package |

End protection/ Woven bags/ Wooden cases |

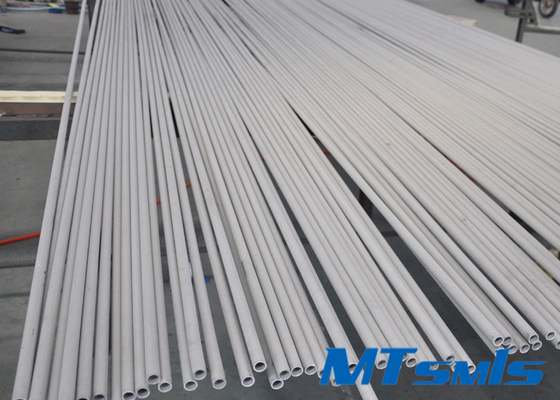

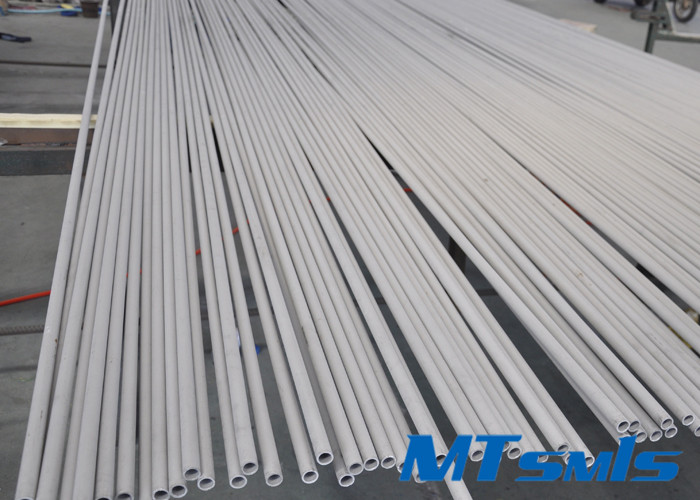

UNS N06600 Bright Annealed Tube:

UNS N06600 Bright Annealed Tubing is a seamless tube made of high-performance nickel-chromium alloy with excellent high-temperature oxidation resistance and corrosion resistance. The main components of the alloy are nickel (about 72%), chromium and iron, which give it excellent structural stability and stress corrosion resistance at high temperatures. After bright annealing, the surface of the tube is smooth and clean, and the internal stress is released, which further improves its corrosion resistance and processing performance. It is particularly suitable for applications requiring high cleanliness and precision.

In industrial applications, UNS N06600 bright annealed tubes are widely used in heat exchangers, chemical containers, nuclear power generation equipment, heating element sheaths, aircraft engine components and fluid delivery systems in high-temperature corrosive environments. Its excellent resistance to chloride ion stress corrosion cracking and good mechanical strength make it an ideal choice of tubes for high temperature, high pressure or corrosive atmospheres.

Chemical composition:

| Grade |

C

max |

Si

max |

Mn

max |

P

max |

S

max |

Cr |

Ni |

Mo |

Ti |

N

max |

Cu

max |

Nb |

Al

max |

Co

max |

Zr |

Fe

max |

Tu |

Va |

| Alloy 600/N06600 |

0 |

1 |

1 |

- |

0 |

14-17 |

≥72 |

- |

- |

- |

1 |

- |

- |

- |

- |

6-10 |

- |

- |

| Alloy 601/N06601 |

0 |

1 |

2 |

- |

0 |

21.0-25.0 |

58-63 |

- |

- |

- |

1 |

- |

1.0-1.7 |

- |

- |

- |

- |

- |

| Alloy 625/N06625 |

0 |

1 |

1 |

0 |

0 |

20-23 |

≥58 |

8-10 |

<0.4 |

- |

- |

3.15-4.15 |

≤0.4 |

- |

- |

5.00 remainder |

- |

- |

Physical properties:

| Grade |

Physical Property |

| Y.S |

T.S |

EL. |

HB |

| Alloy 600/N06600 |

205-345 |

550-690 |

35-55 |

≤185 |

| Alloy 601/N06601 |

240-300 |

600-650 |

30-35 |

≤220 |

| Alloy 625/N06625 |

≥345 |

≥760 |

≥30 |

≤220 |

Factory advantages and features:

1. Huxin Pipe, a highly reliable seamless pipe manufacturer with 36 years of experience in pipe production

2. Diversified pipe sizes - in addition to the regular sizes, we can also produce 18 metres and 25 metres pipe extensions.

3. Well-equipped production and inspection - plant facilities include cold rolling mills, annealing furnaces, pickling baths, ultrasonic eddy current integration, and physical and chemical laboratories

4. Complete quality control process - in addition to factory technicians, full-time MTSCO quality inspectors are on site before, during and after production.

5. Complete certifications - we have ISO/PED/AD2000/M650 certifications.

Introduction to Quality Control Inspection Methods:

Quality Assurance for Raw Materials

Our raw materials, sourced from esteemed steel mills such as Baosteel and Tsingshan, undergo stringent warranty and PMI checks to ensure top-notch quality. Stringent PMI checks and other inspections guarantee compliance with material specifications.

Supervised Production Process

From cold rolling, cold drawing, annealing, to pickling and surface treatment, 321 stainless tube manufacturing process is meticulously overseen. Skilled engineers, equipped with advanced tools, supervise each phase and capture detailed records through photography. Process cards guarantee precision and traceability throughout production.

Quality Assurance Before Shipment

Our dedicated QC team conducts comprehensive inspections, encompassing appearance, PMI, size, quantity, and more. Mechanical, hardness, ultrasonic, eddy current, and hydraulic tests are carried out. We also welcome third-party evaluations (SGS, TUV, BV) and ensure secure packaging and container reinforcement to ensure product integrity during transportation.

Product package:

| Product |

Packaging |

| LCL PIPE |

Plywood crate + protective pipe caps on both ends |

| FCL PIPE |

Woven bag + protective pipe caps on both ends |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!