Product Description

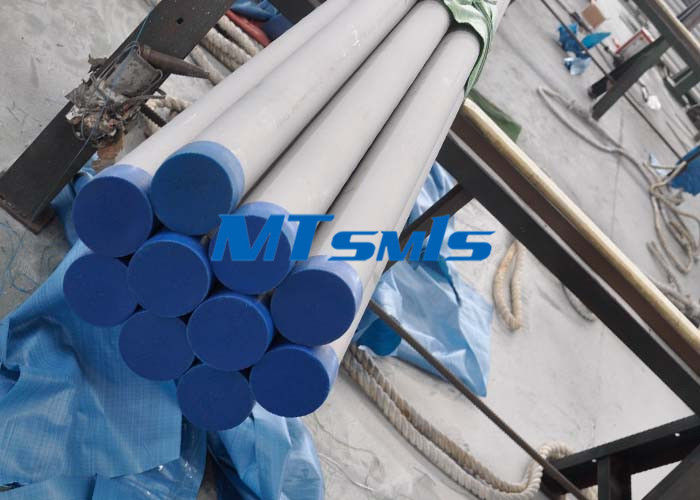

ASTM A790 / ASME SA790 Duplex Steel Pipe For Heat Coils, 6000mm Stainless Seamless Pipe

Most of 2507 duplex steel pipes are produced by cold drawn method . The alloy has higher yield

strength and lower ductility than austenitic steels so fabricators may fid that higher forming forces , increased radius of bending , and increased allowance for springback are necessary . Deep drawing , stretch forming , and similar processes are more difficult to perform on 2507 than on an austenitic

stainless steel . When forming requires more than 10% cold deformation , a solution anneal and quench

are recommended . And finished cold drawn duplex steel pipe , manufacturer should be solution annealed and quenched . The minimum annealing tempeture is 19250F . Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed .

Material Grade: S32205, S31803, S32304, S32750, F51, F53, 2205, 2507 etc

Outer Diameter:10.3mm-1219mm

Wall Thickness: 1.24mm-59.54mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM A789; ASTM A790; EN 10216-5ect.

Process Method: Cold Drawn or Cold Rolled

Application

a) Petroleum

b) Chemical industry

c) Instrument

d) Industrial transportation

e) Mechanical structure industry

f) Need high corrision ability pipe's industry, such as offshore industry etc

Advantages

a) Superior surface finish,

b) Better mechanical property

c) More precise dimension

d) Perfect inspection method and inspection equipment

| Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

N |

| max |

max |

max |

max |

max |

| UNS S32750 |

0.03 |

0.8 |

1.2 |

0.03 |

0.015 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

0.24-0.32 |

| UNS S31803 |

0.03 |

1 |

2 |

0.02 |

0.02 |

21.0-23.0 |

4.5-6.5 |

2.5-3.5 |

0.08-0.20 |

| UNS S31500 |

0.03 |

1 |

1.2-2.0 |

0.03 |

0.03 |

18.0-19.0 |

4.5-5.5 |

2.5-3.5 |

0.05-0.10 |

| Physical Properties |

| |

|

|

|

|

| Grade |

Y.S.MPa min |

T.S.Mpa min |

Elongation % |

Hardness HRC |

| UNS S32750 |

550 |

800 |

15 |

20 |

| UNS S31803 |

450 |

620 |

25 |

20 |

| UNS S31500 |

440 |

630 |

30 |

20 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!