Product Description

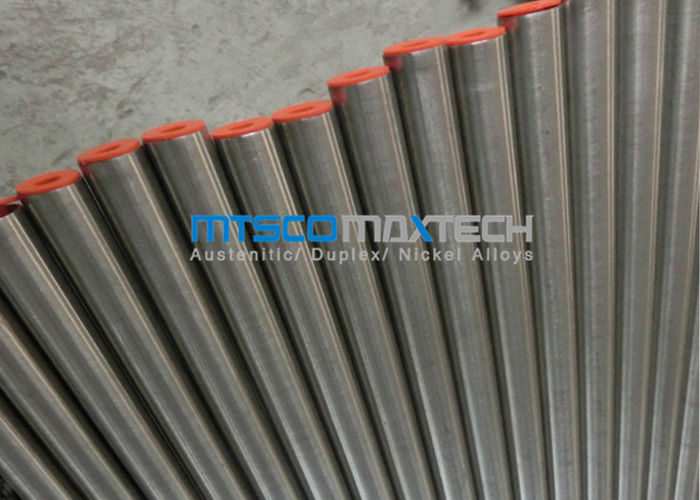

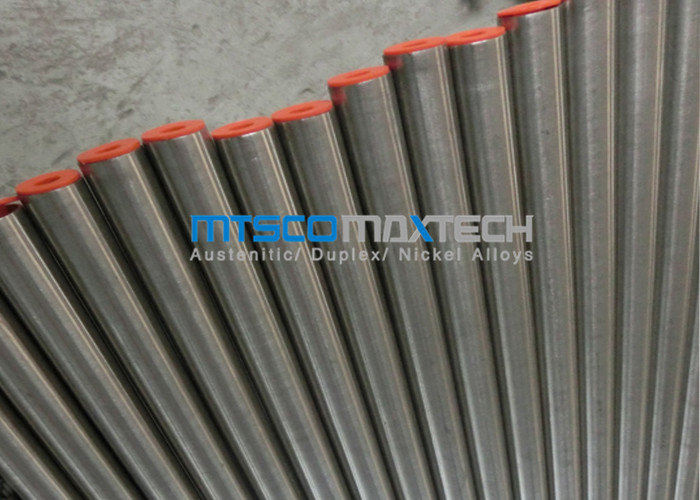

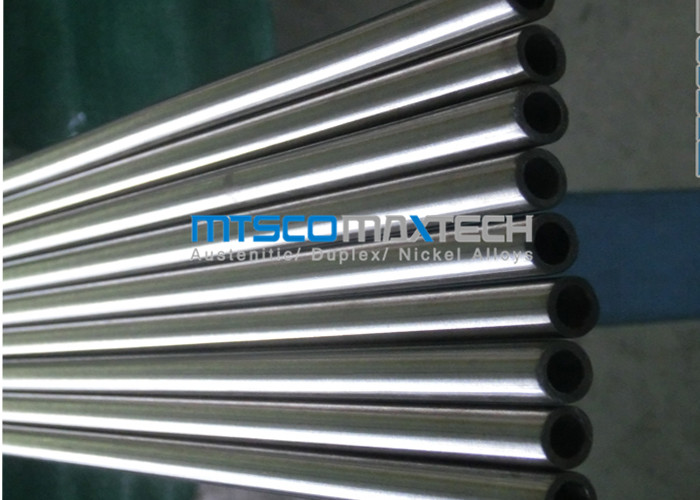

ASTM B622 Alloy C22 Nickel Alloy Tubing With Bright Annealed Surface For Superheater

1. Material Grade: UNS N10276, UNS N10001, UNS N10665, UNS N10675, UNS N06022, N08800, N08825, N04400; etc

2. Outer Diameter: 6.35mm-114.3mm

Wall Thickness: 1.65mm-11.13mm

3. Length: Normally fixed length 6m, can as per customer’s requirement

4. Standard: ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

5. Technology : Cold Drawn / Cold Rolled

Chemical composition

| % |

Ni |

Cr |

Mo |

Fe |

W |

Co |

C |

Mn |

Si |

P |

S |

V |

| min |

balance |

20.0 |

12.5 |

2.0 |

2.5 |

|

|

|

|

|

|

|

| max |

22.5 |

14.5 |

6.0 |

3.5 |

2.5 |

0.015 |

0.50 |

0.08 |

0.020 |

0.020 |

0.35 |

Physical properties

| Density |

8.69 g/cm3 |

| Melting range |

1325-1370℃ |

| Features |

UNS N06200 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including UNS N10276,UNS N06455 and UNS N06625. UNS N06200 has outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams. So it can be used where “upset” conditions are likely to occur or in multi-purpose plants. UNS N06200 has exceptional resistance to a wide variety of chemical process environments, including strong oxidizers such as ferric and cupric chlorides, chlorine, hot contaminated solutions (organic and inorganic), formic and acetic acids, acetic anhydride, and seawater and brine solutions. It resists the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition. |

| Application |

1.Acetic acid/acetyl oxide

2.Acid dipping

3.Cellophane paper manufacture

4.Chloride system

5. Complicated mixed acid

6.Electrogalvanizing groove roller

7.Expansion bellows

8.Flue gas washer system

9.Geothermal well

10.Fluorine hydride furnace cleaner

|

About MTSCO:

Who MTSCO is?

MTSCO established in 2006, during many years’ development, now becomes a large and professional industrial piping system provider, serving customers from more than 100 countries and regions.

What products can MTSCO provide?

What materials can MTSCO provide?

Austenitic: 304/L/H/N,316/L/H/N/Ti,321/H,309/H,310S,347/H,317/L904L

Duplex steel: 31803,32205,32750,32760

Nickel Alloy:

UNS N10001, N10665, N10675, N06455, N06022, N10276, N06200, N06035, N06030, N06635, N10003, N06002, R30188, N06230, R30556

UNS N06600, N06601, N06617, N06625, N07718, N07750, N08800, N08810, N08811, N08825, N09925, N08926

UNS N04400, N05500

Precipitation-hardening Steels: 254SMO/S31254, 17-4PH, 17-7PH, 15-7PH

Nickel: N4/UNS N02201, N6/UNS N02200

How can MTSCO service customers?

MTSCO's ISO9001 Quality System is issued by TUV. Our full and professional inspection reports contain two parts, one is self-inspection of the requirements beyond ISO9001, which is 100% inspected by our own QC; another is 100% inspected by professional QC teams.

For more information, you are welcome to contact us by email. Thank you for your interest.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!