Product Description

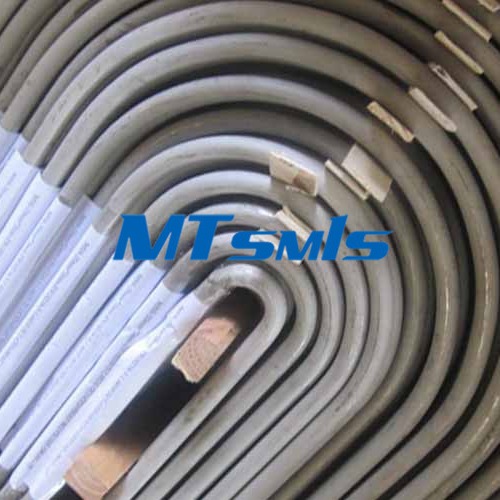

S30400 Annealed Surface U Bend Stainless Steel Heat Exchanger Tube

Heat Exchanger Tube:

Our heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry, water heater industry, air-conditioning industry, etc. This kind of seamless tube has a very important position in our all products.

Heat exchanger tube, choose MTSCO!

Heat Exchanger Tube Chemical Composition :

Austenitic:

TP310S(0Cr25Ni20, 2520)

TP304(0Cr18Ni9)

904L (00Cr20Ni25Mo4.5Cu , UNS N08904)

TP347(0Cr18Ni11Nb)

TP347H(1Cr19Ni11Nb)

TP321(0Cr18Ni10Ti)

TP304L(00Cr19Ni10)

TP316(0Cr17Ni12Mo2)

TP316L(00Cr17Ni14Mo2)

| |

C(max) |

Si(max) |

P(max) |

S(max) |

Cr |

Ni |

Mo |

Ti |

| TP304/1.4301 |

0.080 |

1.00 |

0.045 |

0.030 |

18.0-20.0 |

8.0-10.5 |

|

|

| TP304L/1.4307 |

0.035 |

1.00 |

0.045 |

0.030 |

18.0-20.0 |

8.0-12.0 |

|

|

| TP304H/1.4948 |

0.04-0.10 |

1.00 |

0.045 |

0.030 |

18.0-20.0 |

8.0-12.0 |

|

|

| TP316/1.4401 |

0.080 |

1.00 |

0.045 |

0.030 |

16.0-18.0 |

11.0-14.0 |

2.0-3.0 |

|

| TP316L/1.4404 |

0.035 |

1.00 |

0.045 |

0.030 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

|

| TP316Ti/1.4571 |

0.080 |

1.00 |

0.045 |

0.030 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

0.7>5x(C+N) |

| TP321/1.4541 |

0.080 |

1.00 |

0.045 |

0.030 |

17.0-19.0 |

9.0-12.0 |

|

0.7>5x(C+N) |

| TP317L/1.4449 |

0.080 |

1.00 |

0.045 |

0.030 |

18.0-20.0 |

11.0-14.0 |

3.0-4.0 |

|

| TP347H/1.4912 |

0.04-0.10 |

1.00 |

0.045 |

0.030 |

17.0-19.0 |

9.0-13.0 |

|

|

| TP309S/1.4833 |

0.080 |

1.00 |

0.045 |

0.030 |

22.0-24.0 |

12.0-15.0 |

0.75 |

|

| TP310S/1.4845 |

0.080 |

1.00 |

0.045 |

0.030 |

24.0-26.0 |

19.0-22.0 |

0.75 |

|

Heat Exchanger Tube Specifications :

| DN |

NPS(Inch) |

D(mm) |

SCH5S |

SCH10S |

SCH40S |

STD |

SCH40 |

SCH80 |

XS |

SCH80S |

SCH160 |

XXS |

| 6 |

1/8 |

10.30 |

- |

1.24 |

1.73 |

1.73 |

1.73 |

2.41 |

2.41 |

2.41 |

- |

- |

| 8 |

1/4 |

13.70 |

- |

1.65 |

2.24 |

2.24 |

2.24 |

3.02 |

3.02 |

3.02 |

- |

- |

| 10 |

3/8 |

17.10 |

- |

1.65 |

2.31 |

2.31 |

2.31 |

3.20 |

3.20 |

3.20 |

- |

- |

| 15 |

1/2 |

21.30 |

1.65 |

2.11 |

2.77 |

2.77 |

2.77 |

3.73 |

3.73 |

3.73 |

4.78 |

7.47 |

| 20 |

3/4 |

26.70 |

1.65 |

2.11 |

2.87 |

2.87 |

2.87 |

3.91 |

3.91 |

3.91 |

5.56 |

7.82 |

| 25 |

1 |

33.40 |

1.65 |

2.77 |

3.38 |

3.38 |

3.38 |

4.55 |

4.55 |

4.55 |

6.35 |

9.09 |

| 32 |

1 1/4 |

42.20 |

1.65 |

2.77 |

3.56 |

3.56 |

3.56 |

4.85 |

4.85 |

4.85 |

6.35 |

9.70 |

| 40 |

1 1/2 |

48.30 |

1.65 |

2.77 |

3.68 |

3.68 |

3.68 |

5.08 |

5.08 |

5.08 |

7.14 |

10.15 |

| 50 |

2 |

60.30 |

1.65 |

2.77 |

3.91 |

3.91 |

3.91 |

5.54 |

5.54 |

5.54 |

8.74 |

11.07

|

Heat Exchanger Tube Advantages

a) Advanced technology of cold draw machine

b) Advanced annealing machine

c) Better mechanical property

d) More precise dimension

e) Perfect inspection method and inspection equipment etc

Heat Exchanger Tube Process :

1 . We use Cold Drawn technology to produce U bend tube

2. U bend tubes produce will accordance to customer's drawings

3 . To avoid oxidation, inert gas (Argon) is passed through tubes ID at the required flow rate

4 . The radius is checked for its OD and wall thinning with the recommended specification

5 . We'll choose three different positions or as customers require to make sure tubes quality. We'll do physical properties and micro-structure test

6 . Visual inspection for waviness and cracks is done with Dye Penetrant Test

7 . Each tube is then hydro tested at the recommended pressure to check for leakage

About MTSCO:

Who MTSCO is?

MTSCO established in 2006, during many years’ development, now becomes a large and professional industrial piping system provider, serving customers from more than 100 countries and regions.

What products can MTSCO provide?

What materials can MTSCO provide?

Austenitic: 304/L/H/N,316/L/H/N/Ti,321/H,309/H,310S,347/H,317/L904L

Duplex steel: 31803,32205,32750,32760

Nickel Alloy:

UNS N10001, N10665, N10675, N06455, N06022, N10276, N06200, N06035, N06030, N06635, N10003, N06002, R30188, N06230, R30556

UNS N06600, N06601, N06617, N06625, N07718, N07750, N08800, N08810, N08811, N08825, N09925, N08926

UNS N04400, N05500

Precipitation-hardening Steels: 254SMO/S31254, 17-4PH, 17-7PH, 15-7PH

Nickel: N4/UNS N02201, N6/UNS N02200

How can MTSCO service customers?

MTSCO's ISO9001 Quality System is issued by TUV. Our full and professional inspection reports contain two parts, one is self-inspection of the requirements beyond ISO9001, which is 100% inspected by our own QC; another is 100% inspected by professional QC teams.

Thank you very much for reading this, I wonder if my presentation will help you with your current problem? Looking forward to hearing from you!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!