Product Description

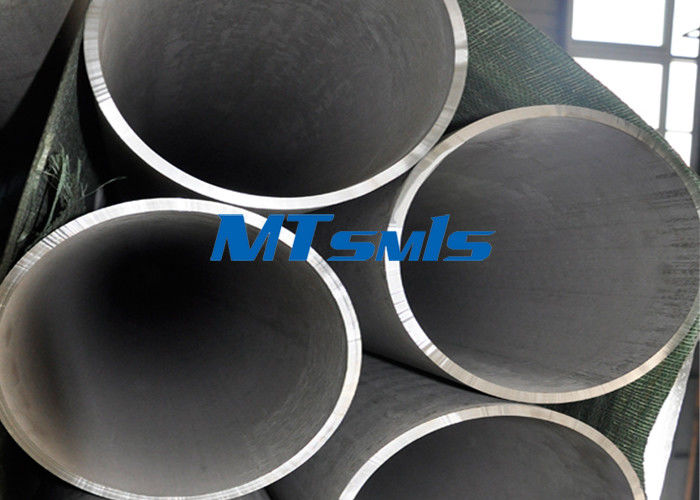

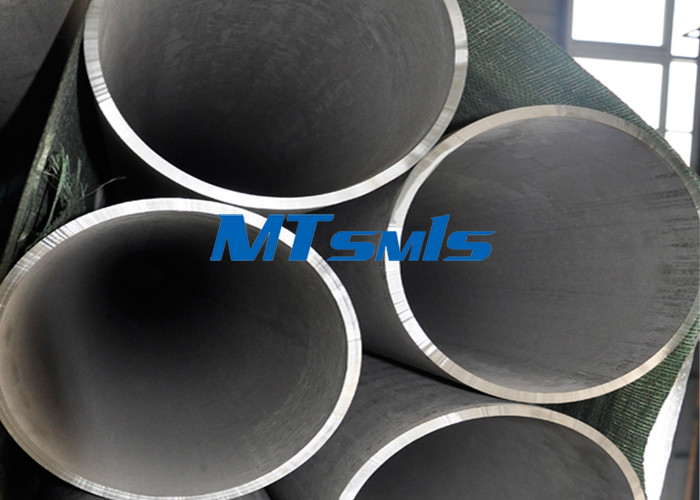

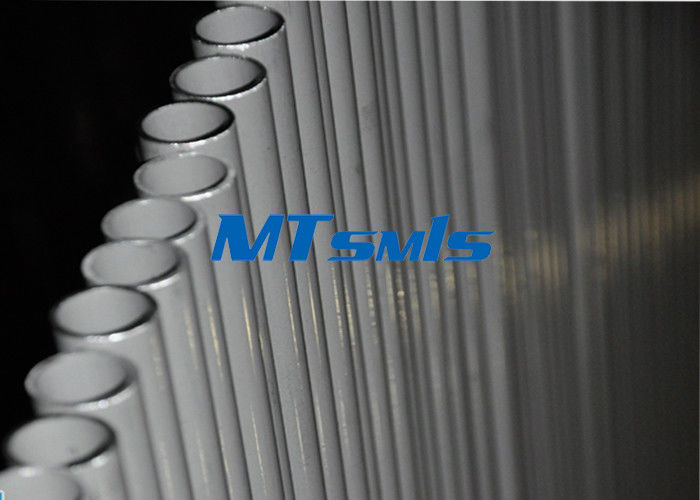

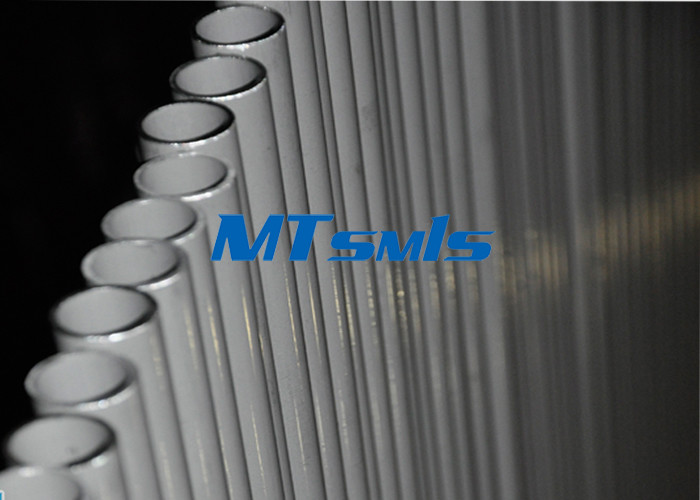

6 Inch UNS S31803 Duplex Steel Pipe Cold Rolled , 1.4410

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series

stainless steels . “ Duplex ” describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex structure is that it combines the favorable qualities of a ferritic alloy ( stress corrosion cracking resistance and high strength ) with those of an austenitic alloy ( ease of fabrication and corrosion resistance ) .

| Material Grade |

S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc |

| Outer Diameter |

10.3mm - 1219mm |

| Wall Thickness |

1.24mm - 59.54mm |

| Length |

as per customer’s requirement |

| Standard |

ASTM A789 ; ASTM A790 ; EN 10216-5ect .

|

1. Price Item: FOB, CFR, CIF or as negotiation

2. Payment: T/T, LC or as negotiation

3. Delivery Time: 30 working days after received your deposit (Normally according to the order quantity)

4. Package Iron case; woven bag or as per customer’s requirement

4. Quality Requirement: Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable

5. Test: NTD(Ultrasonic test, Eddy Current test);

6. Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test);

Metal Test(Metallographic Analysis, Impact Test-High/low temperature);

Chemical Analysis(Photoelectric Emission Spectroscopic)

7. Main Market Europe, Middle East, Southeast Asia, South America. etc

Application :

1 . Petroleum

2 . Chemical industry

3 . Instrument

4 . Industrial transportation

5 . Mechanical structure industry

6 . Need high corrision ability pipe's industry , such as offshore industry etc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!