Product Description

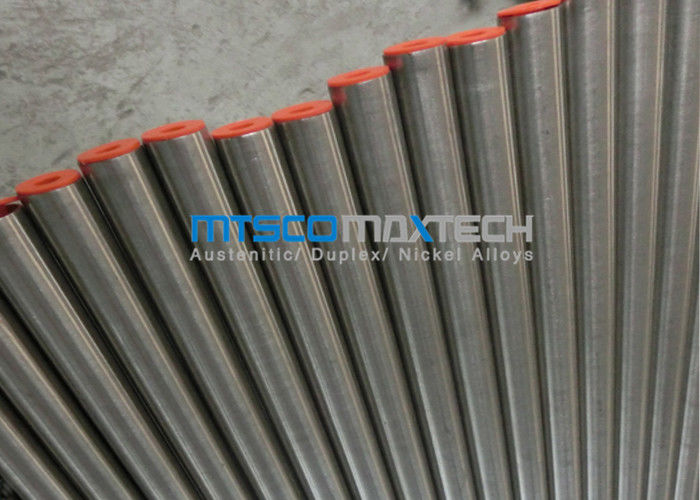

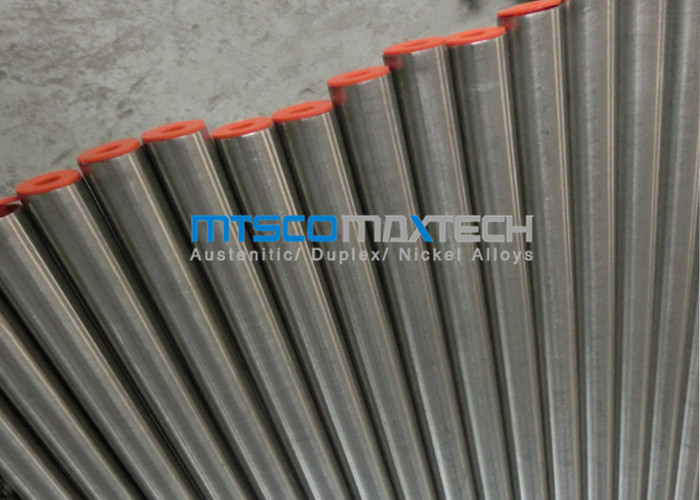

EN10216-5 1.4301 / 1.4306 Stainless Steel Tube With Bright Annealed Surface

EN10216-5 Standard Chemical Composition :

| Steel Grade |

C |

Si |

Mn |

P |

S |

N |

Cr |

Cu |

Mo |

Nb |

Ni |

Ti |

Others |

| max |

|

|

max |

max |

|

|

|

|

|

|

|

|

| Steel Name |

Steel Number |

|

|

|

|

|

|

|

|

|

|

|

|

|

| X2CrNi19-11 |

1.4306 |

0.03 |

≤1 |

≤2 |

0.04 |

0.015 |

≤0.11 |

18.00 - 20.00 |

- |

- |

- |

8.00 - 10.00 |

- |

- |

| X5CrNi18-10 |

1.4301 |

0.07 |

≤1 |

≤2 |

0.04 |

0.015 |

≤0.11 |

17.00 - 19.50 |

- |

- |

- |

8.00 - 10.50 |

- |

- |

| X6CrNiTi18-10 |

1.4541 |

0.08 |

≤1 |

≤2 |

0.04 |

0.015 |

≤0.11 |

17.00 - 19.00 |

- |

- |

- |

9.00 - 12.00 |

5xC to 0.70 |

- |

| X6CrNiNb18-10 |

1.4550 |

0.08 |

≤1 |

≤2 |

0.04 |

0.015 |

- |

17.00 - 19.00 |

- |

- |

10xC to 1.00 |

9.00 - 12.00 |

- |

- |

| X2CrNiMo17-12-2 |

1.4404 |

0.03 |

≤1 |

≤2 |

0.04 |

0.015 |

≤0.11 |

16.50 - 18.50 |

- |

2.00 - 2.50 |

- |

10.00 - 13.00 |

- |

- |

| X5CrNiMo17-12-2 |

1.4401 |

0.07 |

≤1 |

≤2 |

0.04 |

0.015 |

≤0.11 |

16.50 - 18.50 |

- |

2.00 - 2.50 |

- |

10.00 - 13.00 |

- |

- |

| X6CrNiMoTi17-12-2 |

1.4571 |

0.08 |

≤1 |

≤2 |

0.04 |

0.015 |

- |

16.50 - 18.50 |

- |

2.00 - 2.50 |

- |

10.50 - 13.50 |

5xC to 0.70 |

- |

Grade: TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H

Standard: ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc

Size: OD:3.18-101.6mm

WT:0.5-20mm

Length: Max.12M

Advantage: Superior surface finish ,better mechanical property; more precise dimension; perfect inspection method and inspection equipment

Application: Boiler tube applies to petroleum,chemical industry,electric power,boiler,high temperature

resistant,low temperature resistant,corrosion resistant.The size can be made according

to the customers requirements.High pressure boiler pipe applies to container,petrochemical

and so on.Note:Generally,high pressure boiler pipe’s working pressure above 9.88Mpa and

working temperature between 450 to 650.

Package: Plastic in both ends, then packed in iron case

Test :

1 . Corrosion Test : Conducted only when specially requested by the client

2 . Chemical Analysis : Test done as per required quality standards

3 . Destructive / Mechanical Testing : Tensile / Hardness / Flattening / Flaring

4 . Eddy Current Testing : 100% or partial test

5 . Hydrostatic Testing : 100%

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!